Unboxing - what was in it

I received the CNC milling machine and it came in a large cardboard box. It weighed 22 Kgs with a board underneath it.

After opening it up, and removing the packaging. There was one box for the steppers, controller, documents and tools, and then under that the machine.

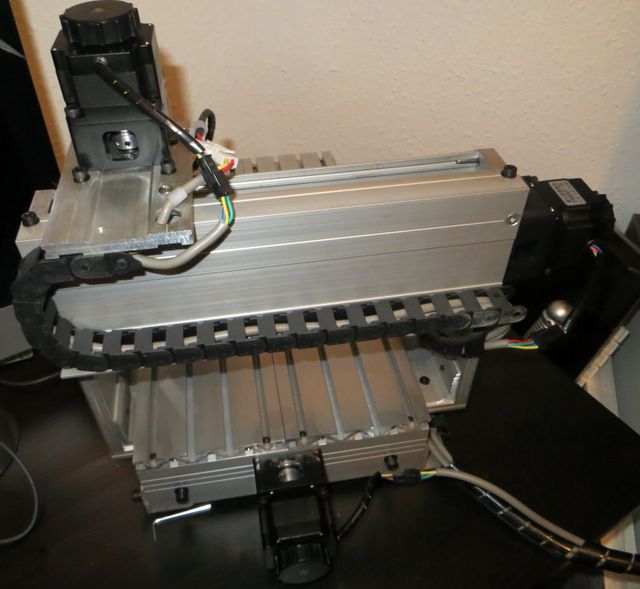

First, I carefully removed the machine and placed it on my desk. I’d cleared some suitable space for it. I set the CNC mill up so that the bed was facing the wall, so the gantries and business end were closest to me. The stepper motors weren’t attached, and it was also pretty dusty. I gave it a quick pass with a handy vac, and wiped down the surfaces (NOT THE BEARINGS!).

I then examined the contents of the control box. There were a couple of bits of paper, a CD with Chinese writing on it, the 3 steppers and the tools. The tool box had spare screws, spindle accessories, a set of alan keys, and clamping tools.

The next stage was to fit the steppers using an alan key to screw them in place. I do 2 opposite corners first.

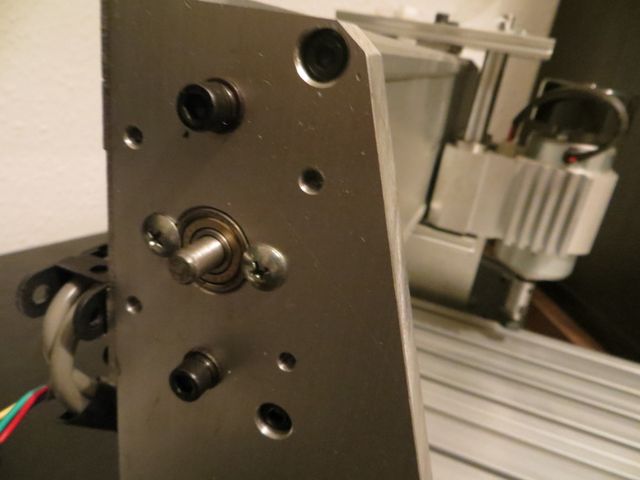

Then I used another smaller Alan key to tighten the collars onto the lead screws. I was able to then verify this moved by turning the knobs at the end of the steppers. I plugged the cables into the steppers and the spindle, using the handy cable guides at the top of the z axis to stop the spindle cable getting in the way of X axis movements.

I then brought out the control box. This came with 5 layers of bubble wrap. After unwrapping it, I plugged the cables into it.

I then did the initial tests. These were turning on the control box, ensuring the emergency stop was not pressed. The fan started up fine. I then turned on the spindle, and heard it rev up nicely. I turned the spindle off, and then checked the steppers. I tried to manually turn each stepper motor, noting the stiffness that in theory shows that the steppers are connected to their controllers. All was fine.

I have also recorded some video footage of this. If anything survives editing, I will put that on youtube.